Equipment Calibration Record

Track calibration status and maintain measurement equipment accuracy for quality assurance compliance.

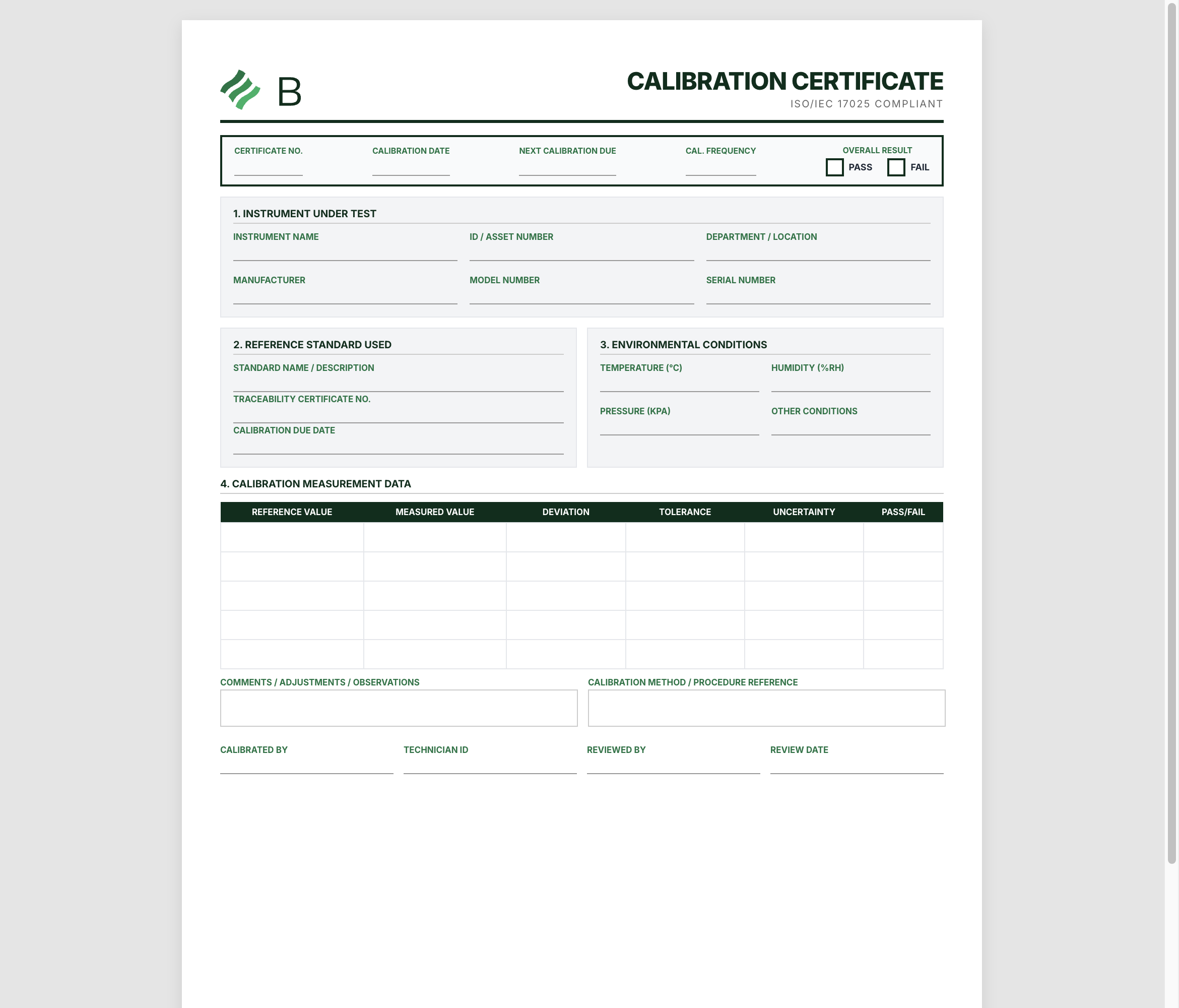

About This Template

The Equipment Calibration Record is essential for maintaining measurement accuracy and meeting ISO 9001 and other quality management standards. This template helps you document calibration activities for all measuring and test equipment, ensuring traceability and compliance. Regular calibration prevents measurement errors that can lead to quality issues, scrap, and customer complaints. The template includes fields for equipment details, calibration standards used, results, and certification information, providing a complete audit trail for regulatory inspections.

Key Features

How to Use This Template

- Record complete equipment identification and serial numbers

- Document calibration standards and reference equipment used

- Record as-found and as-left measurement readings

- Apply pass/fail criteria based on tolerance specifications

- Capture technician information and certification details

- Schedule next calibration and apply calibration labels

Ideal For

Common Use Cases

Use this template in a live digital workflow

Start with this downloadable form, then transition to real-time production execution, quality tracking, and automated reporting with Bulk.

Ready to unify your operations?

See how Bulk can transform your manufacturing floor with a personalized demo.