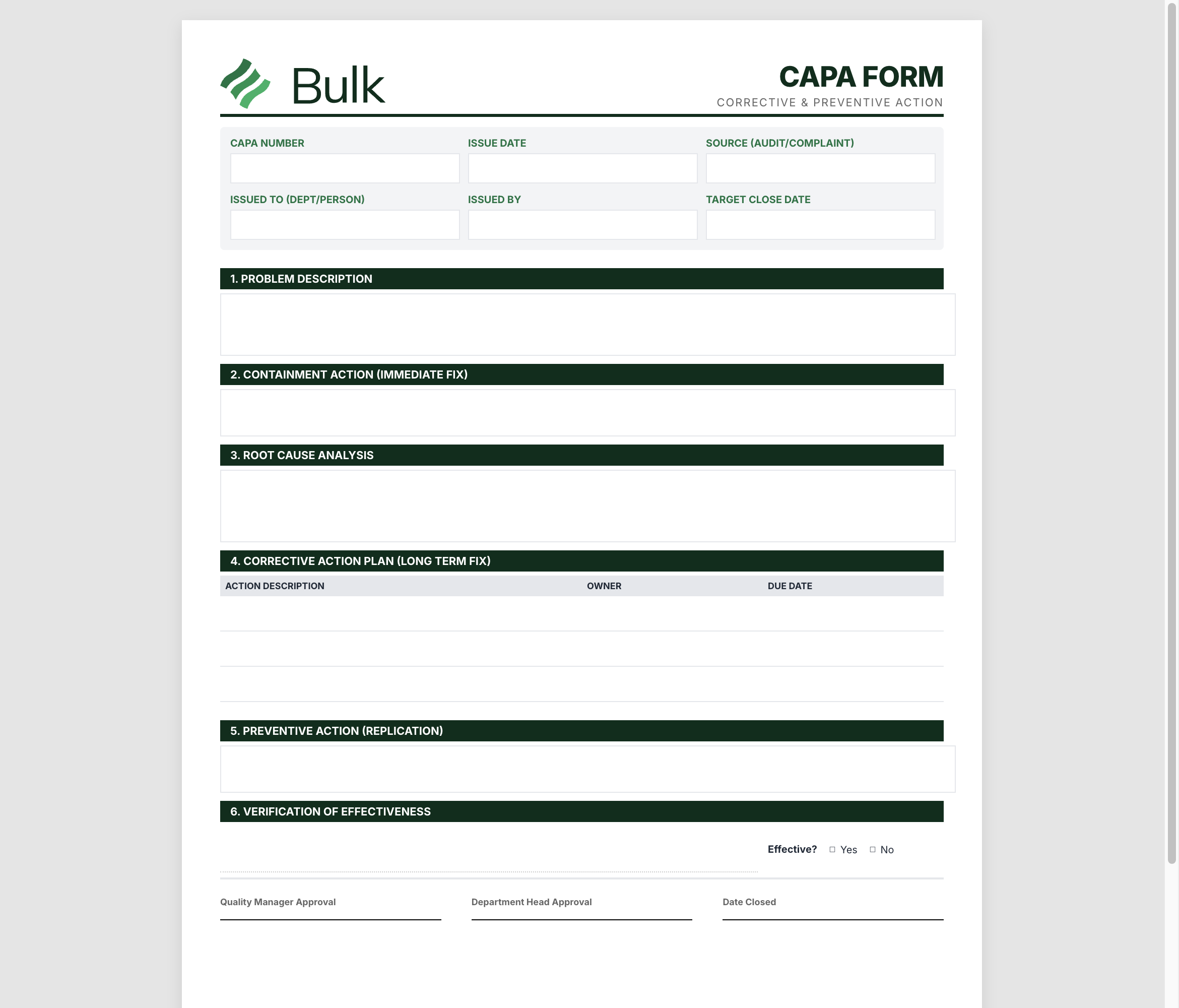

CAPA Form (Corrective & Preventive Action)

Systematic approach to identifying, investigating, and resolving quality issues with preventive measures.

About This Template

The CAPA (Corrective and Preventive Action) Form is a fundamental quality management tool required by ISO 9001, FDA regulations, and other quality standards. This template provides a structured process for identifying quality problems, determining root causes, implementing corrective actions to fix current issues, and establishing preventive actions to prevent recurrence. The form guides teams through investigation, risk assessment, solution development, and verification of effectiveness, ensuring quality issues are resolved systematically and permanently.

Key Features

How to Use This Template

- Document the problem, non-conformance, or opportunity for improvement

- Conduct root cause analysis using appropriate tools (5 Whys, fishbone)

- Develop corrective actions to address immediate problem

- Plan preventive actions to eliminate root causes system-wide

- Implement actions with assigned owners and target dates

- Verify effectiveness and document lessons learned

Ideal For

Common Use Cases

Use this template in a live digital workflow

Start with this downloadable form, then transition to real-time production execution, quality tracking, and automated reporting with Bulk.

Ready to unify your operations?

See how Bulk can transform your manufacturing floor with a personalized demo.