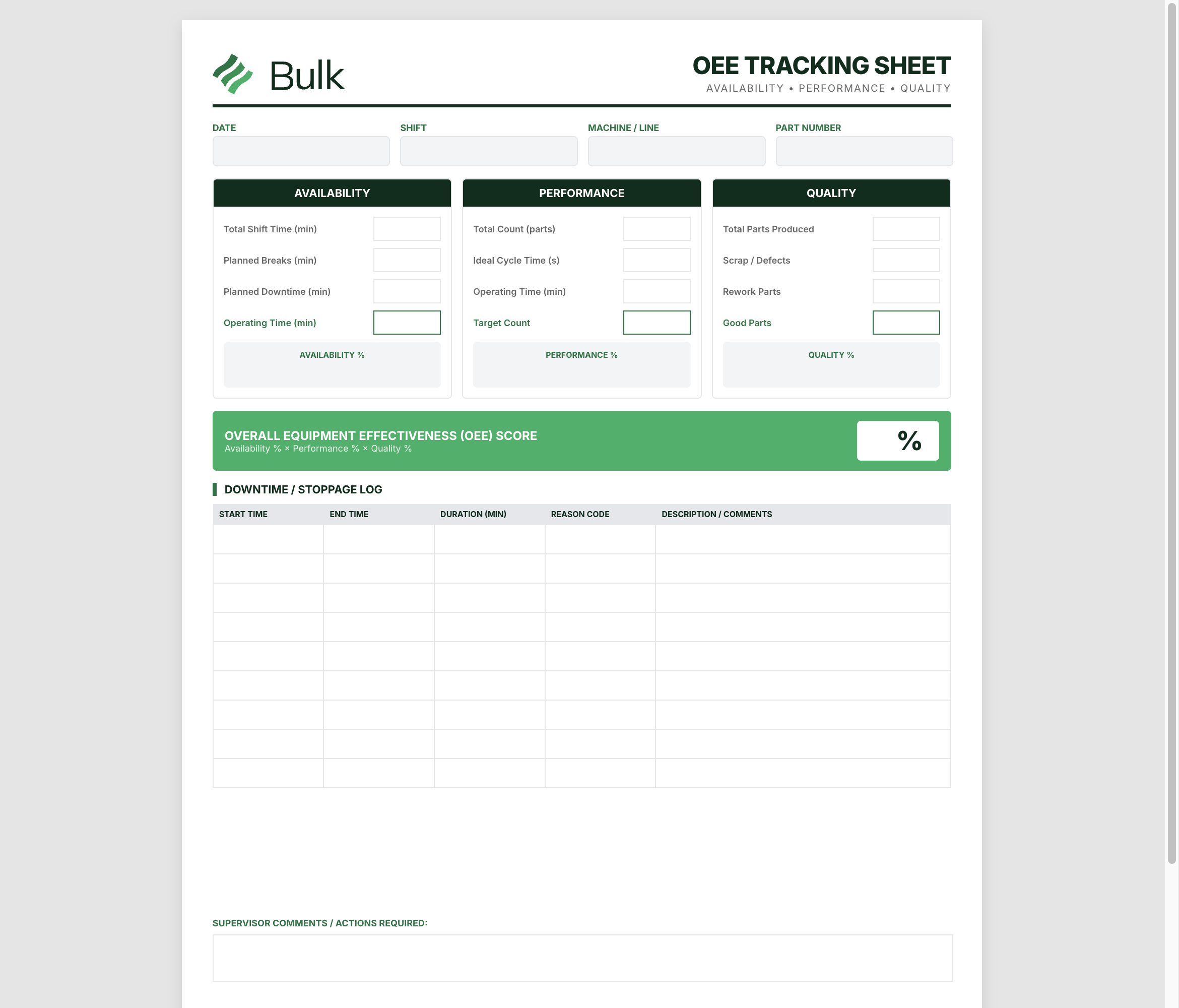

OEE Tracking Sheet (Overall Equipment Effectiveness)

Measure equipment productivity through availability, performance, and quality metrics.

About This Template

The OEE (Overall Equipment Effectiveness) Tracking Sheet is the gold standard metric for measuring manufacturing productivity, combining availability, performance, and quality into a single percentage. OEE provides a clear picture of how effectively equipment is running, identifying the six big losses: breakdowns, setup/adjustments, small stops, reduced speed, startup defects, and production defects. This template guides users through calculating each OEE component and highlights improvement opportunities. World-class OEE is 85%, but most manufacturers operate in the 40-60% range, representing enormous improvement potential. Tracking OEE focuses improvement efforts on the most impactful areas.

Key Features

How to Use This Template

- Record planned production time and all downtime events

- Document total parts produced and target cycle time

- Count good parts and defective/reworked parts

- Calculate Availability = (Operating Time - Downtime) / Operating Time

- Calculate Performance = Actual Output / (Operating Time / Ideal Cycle Time)

- Calculate Quality = Good Parts / Total Parts, then multiply all three for OEE

Ideal For

Common Use Cases

Use this template in a live digital workflow

Start with this downloadable form, then transition to real-time production execution, quality tracking, and automated reporting with Bulk.

Ready to unify your operations?

See how Bulk can transform your manufacturing floor with a personalized demo.