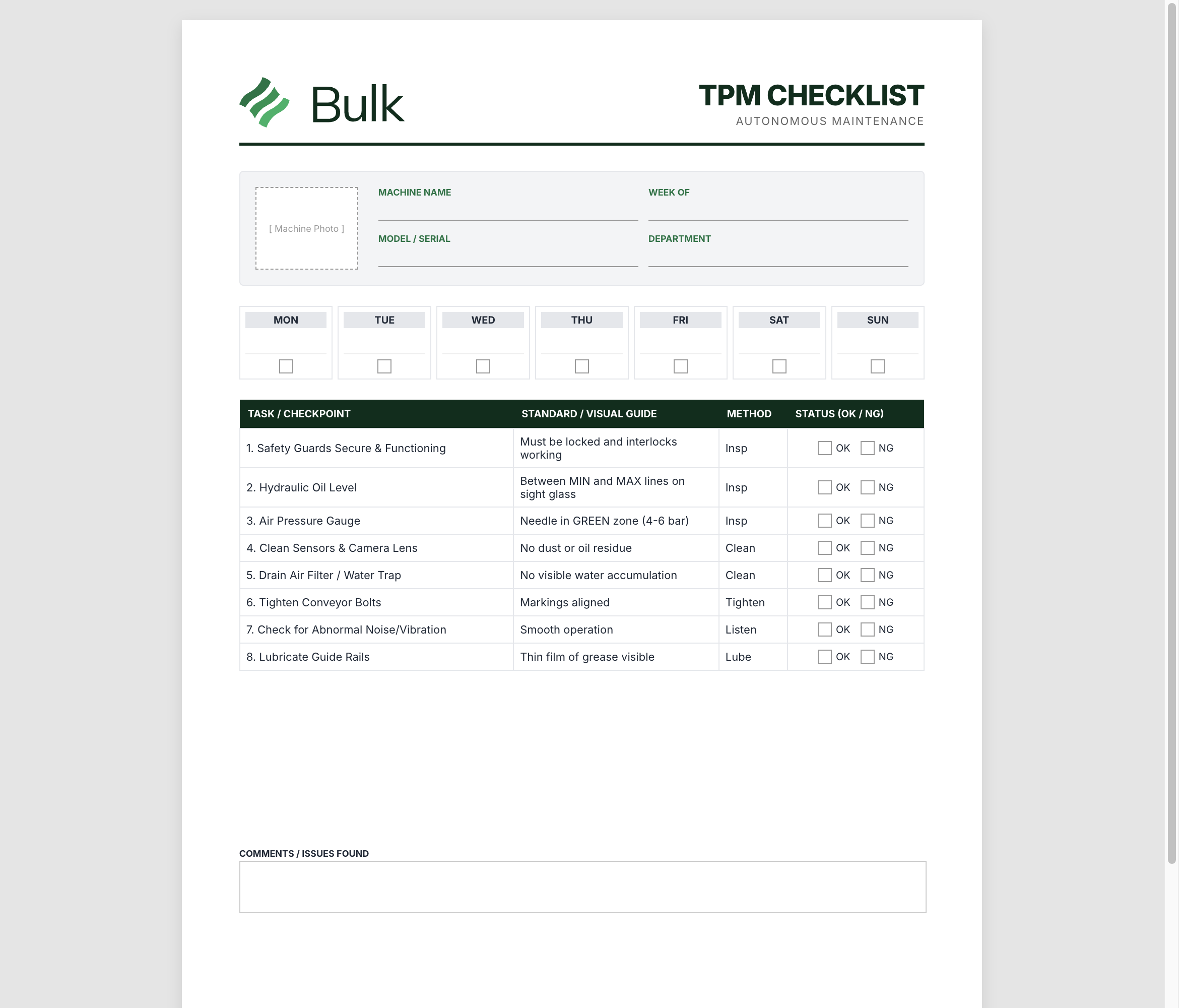

TPM Checklist (Total Productive Maintenance)

Operator-performed equipment maintenance checklist for autonomous maintenance and TPM programs.

About This Template

The TPM (Total Productive Maintenance) Checklist is a fundamental tool for implementing autonomous maintenance, one of the eight pillars of TPM. This template empowers operators to take ownership of basic equipment care through daily cleaning, inspection, and minor maintenance activities. By involving operators in equipment care, TPM programs reduce breakdowns, improve OEE, extend equipment life, and develop operator equipment knowledge. The checklist format provides a structured daily routine for cleaning, lubricating, inspecting, and tightening equipment, catching small problems before they become major breakdowns. TPM shifts maintenance culture from reactive repair to proactive prevention.

Key Features

How to Use This Template

- Complete checklist at start or end of every shift

- Clean equipment thoroughly while inspecting for abnormalities

- Check all lubrication points and add lubricant as scheduled

- Inspect for loose bolts, leaks, unusual noise, or vibration

- Report any problems found immediately for maintenance action

- Track equipment condition trends to predict maintenance needs

Ideal For

Common Use Cases

Use this template in a live digital workflow

Start with this downloadable form, then transition to real-time production execution, quality tracking, and automated reporting with Bulk.

Ready to unify your operations?

See how Bulk can transform your manufacturing floor with a personalized demo.