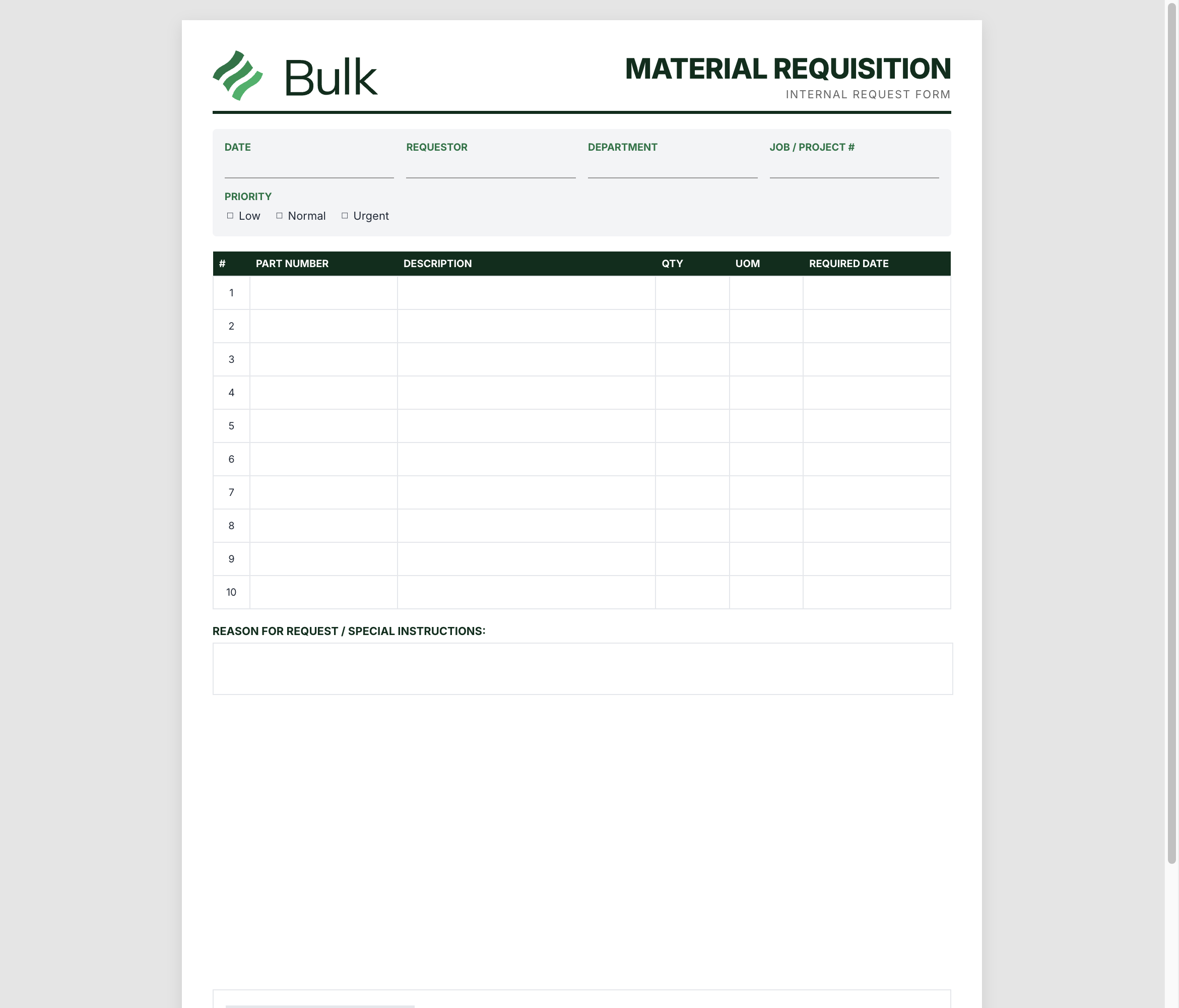

Material Requisition Form

Request materials from inventory with proper authorization and cost allocation tracking.

About This Template

The Material Requisition Form provides controlled access to inventory and supplies while maintaining accurate cost allocation and usage tracking. This template requires proper authorization before materials are issued, ensuring that inventory is used appropriately and costs are charged to the correct departments, jobs, or projects. The requisition system prevents unauthorized material usage, supports inventory accuracy, and provides audit trail for material consumption. By documenting who requested materials, for what purpose, and in what quantity, organizations maintain control over inventory costs and can identify opportunities for waste reduction.

Key Features

How to Use This Template

- Complete form specifying exact materials needed

- Include job number or cost center for proper charging

- Obtain supervisor approval before submitting to stores

- Submit to warehouse or stores for material issue

- Verify quantities and items received against requisition

- File completed forms for accounting and audit trail

Ideal For

Common Use Cases

Use this template in a live digital workflow

Start with this downloadable form, then transition to real-time production execution, quality tracking, and automated reporting with Bulk.

Ready to unify your operations?

See how Bulk can transform your manufacturing floor with a personalized demo.