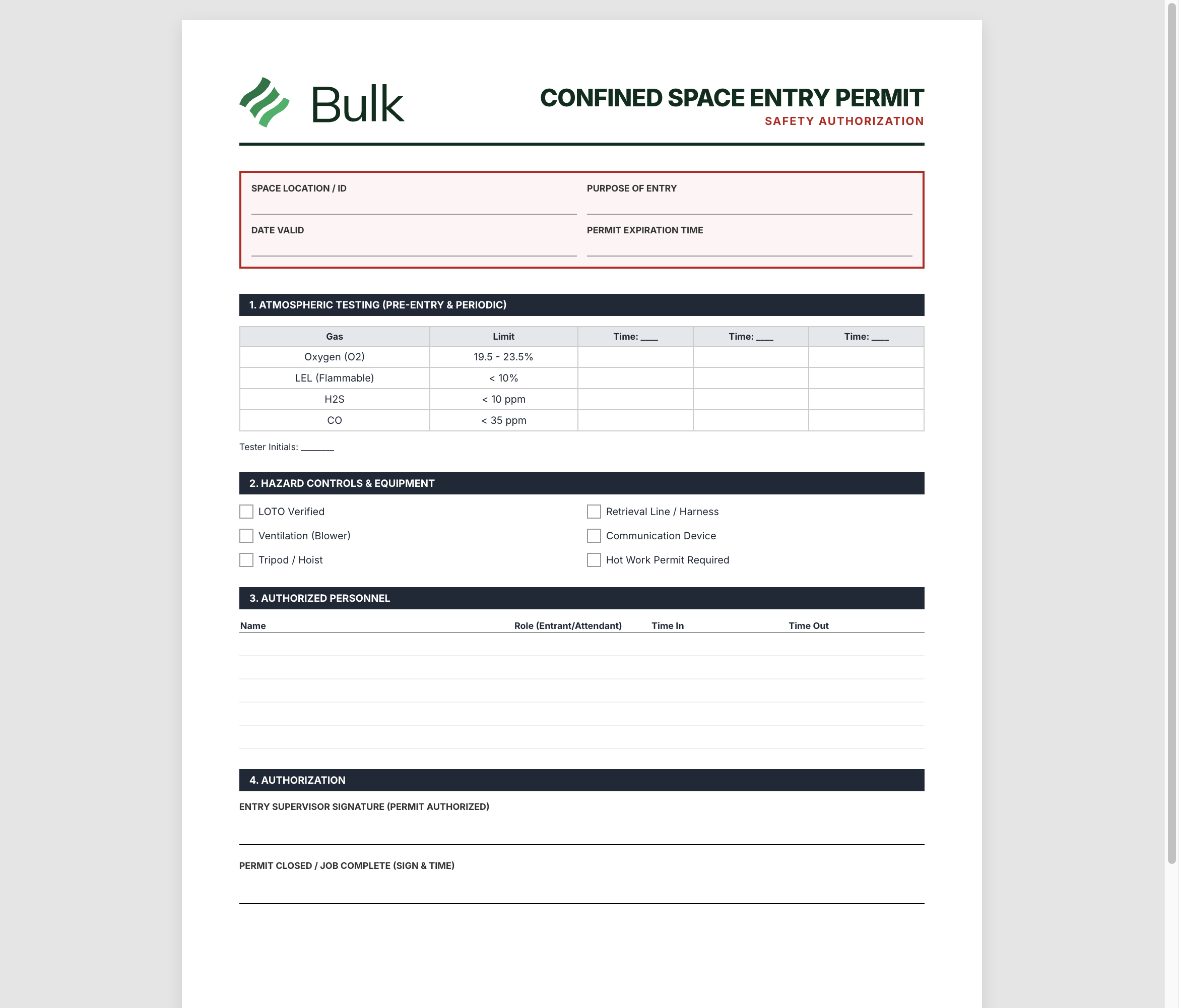

Confined Space Entry Permit

OSHA-compliant permit for safe entry into confined spaces with hazard assessment and controls.

About This Template

The Confined Space Entry Permit is a critical safety document required by OSHA 1910.146 for permit-required confined spaces. This template ensures that all hazards are identified, tested, and controlled before personnel enter tanks, vessels, manholes, or other confined areas. The permit system requires atmospheric testing, ventilation verification, emergency equipment readiness, and continuous monitoring throughout the entry operation. Using this permit helps prevent confined space fatalities and serious injuries caused by oxygen deficiency, toxic atmospheres, or engulfment hazards.

Key Features

How to Use This Template

- Identify and evaluate the confined space before any entry

- Complete atmospheric testing for oxygen, flammability, and toxics

- Document all required safety controls and equipment

- Verify rescue equipment and emergency procedures are ready

- Obtain signatures from entry supervisor, attendant, and entrants

- Maintain continuous atmospheric monitoring during entry

Ideal For

Common Use Cases

Use this template in a live digital workflow

Start with this downloadable form, then transition to real-time production execution, quality tracking, and automated reporting with Bulk.

Ready to unify your operations?

See how Bulk can transform your manufacturing floor with a personalized demo.