Hot Work Permit

Fire prevention permit system for welding, cutting, grinding, and other spark-producing operations.

About This Template

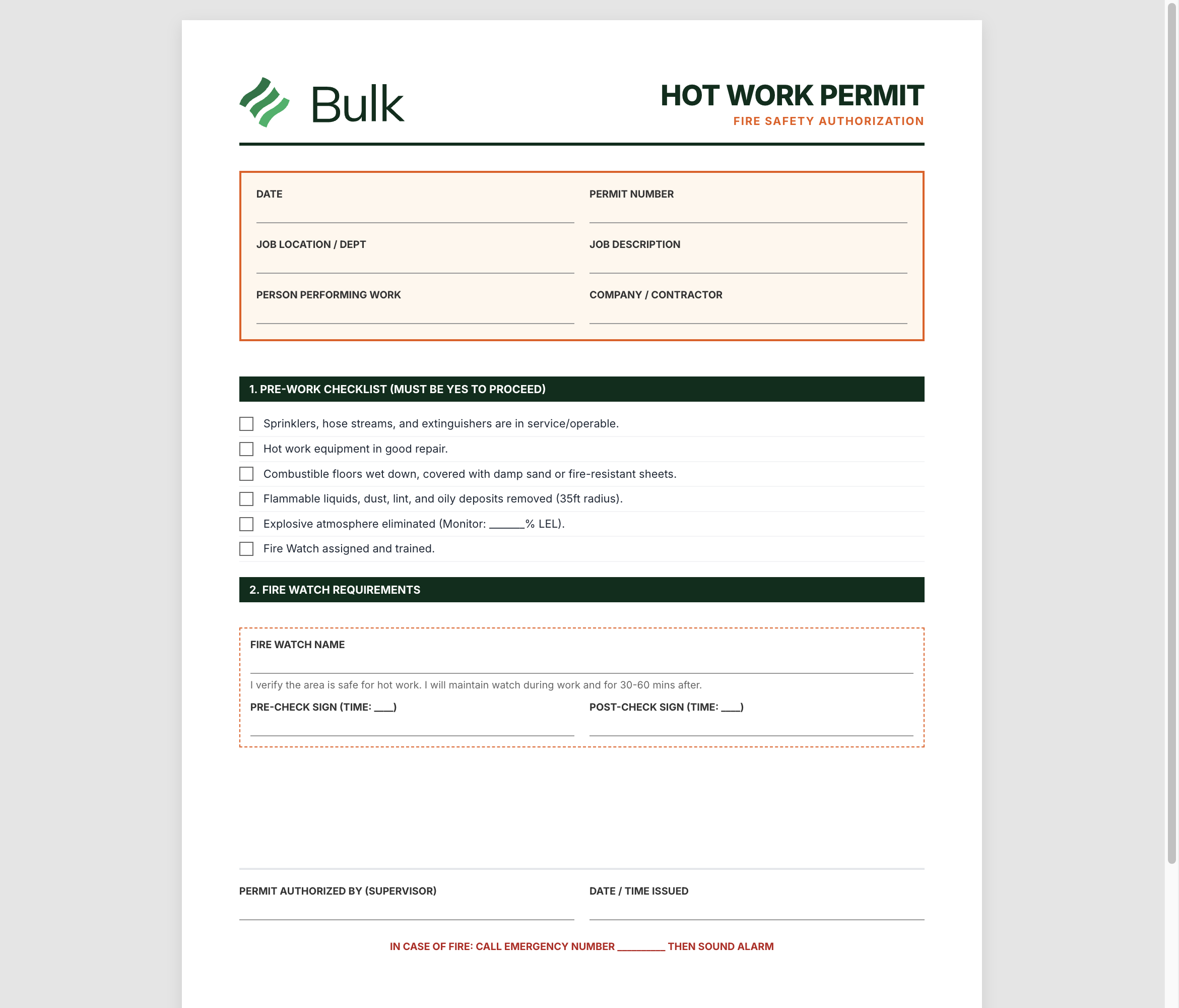

The Hot Work Permit is a critical fire prevention control required whenever welding, cutting, grinding, or other spark-producing work is performed outside of designated hot work areas. This permit system, aligned with OSHA 1910.252 and NFPA 51B standards, ensures that fire hazards are identified and controlled before any hot work begins. The template requires verification of fire watch personnel, fire extinguisher availability, combustible materials removal, and post-work monitoring. Hot work is a leading cause of industrial fires, and this permit system provides the structured approach needed to prevent devastating losses.

Key Features

How to Use This Template

- Complete permit before any welding, cutting, or grinding work

- Inspect work area for combustible materials within 35 feet

- Remove or protect all flammable materials and coverings

- Assign trained fire watch personnel with appropriate equipment

- Verify fire extinguishers and emergency procedures are in place

- Maintain fire watch during and after work as specified

Ideal For

Common Use Cases

Use this template in a live digital workflow

Start with this downloadable form, then transition to real-time production execution, quality tracking, and automated reporting with Bulk.

Ready to unify your operations?

See how Bulk can transform your manufacturing floor with a personalized demo.