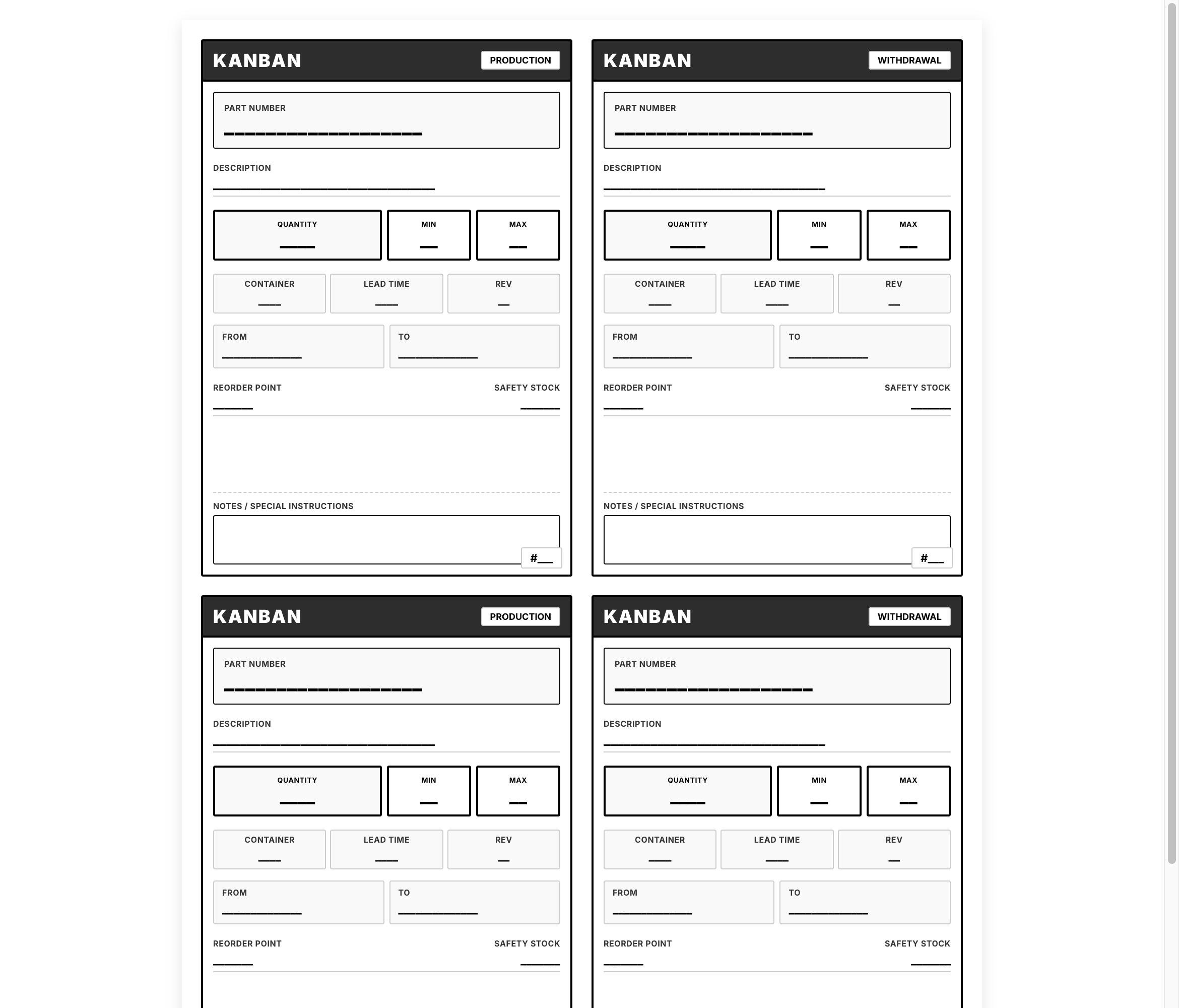

Kanban Card Template

Visual signal cards for pull-based material replenishment and production control.

About This Template

The Kanban Card Template is a fundamental tool for implementing lean pull systems and just-in-time material flow. Kanban cards serve as visual signals that trigger material replenishment or production only when needed, preventing overproduction and excess inventory. This template includes essential information for material identification, storage locations, quantities, and reorder points. By replacing push-based scheduling with pull signals, organizations reduce inventory, improve flow, expose hidden problems, and create more flexible, responsive production systems aligned with actual customer demand.

Key Features

How to Use This Template

- Create cards for each part number managed with kanban system

- Determine optimal kanban quantity and number of cards needed

- Attach cards to containers at point of use

- When container is opened, send kanban card to replenishment area

- Use cards to trigger production or supplier replenishment

- Continuously adjust kanban quantities based on actual consumption

Ideal For

Common Use Cases

Use this template in a live digital workflow

Start with this downloadable form, then transition to real-time production execution, quality tracking, and automated reporting with Bulk.

Ready to unify your operations?

See how Bulk can transform your manufacturing floor with a personalized demo.