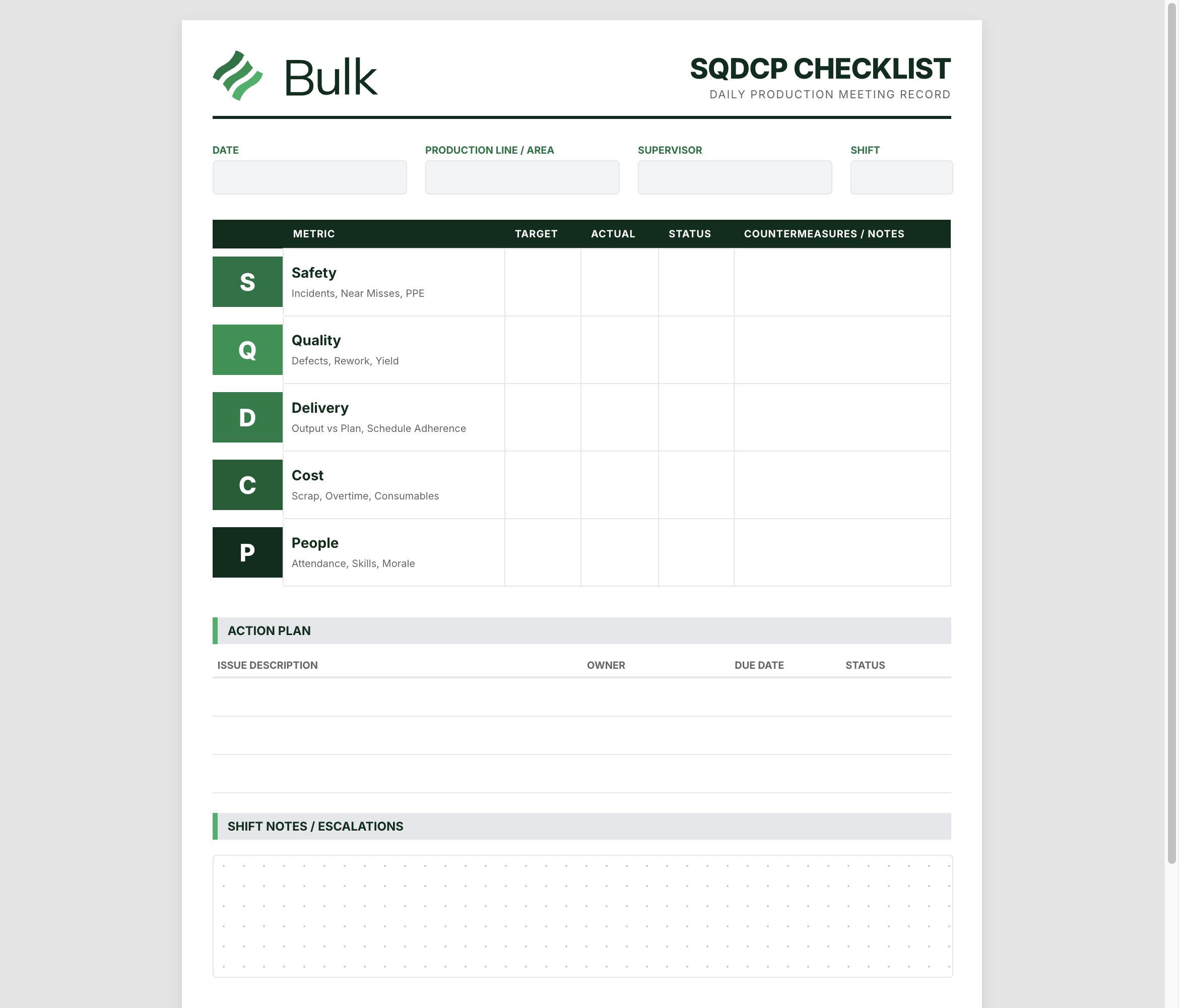

SQDCP Daily Meeting Checklist

Structure daily production stand-ups covering Safety, Quality, Delivery, Cost, and People.

About This Template

The SQDCP Daily Meeting Checklist provides a structured agenda for focused daily production meetings that keep teams aligned on what matters most. SQDCP (Safety, Quality, Delivery, Cost, People) is a lean management framework that ensures balanced focus across all critical performance dimensions. This template guides teams through reviewing yesterday’s performance, addressing current issues, and planning today’s priorities in just 15-20 minutes. Daily SQDCP meetings create rhythm, accountability, and rapid problem escalation in manufacturing operations, dramatically improving response time to issues and team coordination compared to traditional longer, less frequent meetings.

Key Features

How to Use This Template

- Conduct meeting daily at same time and location (15-20 minutes)

- Stand up to maintain energy and focus

- Review each SQDCP category in order with key metrics

- Identify and escalate problems requiring help

- Assign action items with owners and target completion

- Document meeting on checklist and post visually

Ideal For

Common Use Cases

Use this template in a live digital workflow

Start with this downloadable form, then transition to real-time production execution, quality tracking, and automated reporting with Bulk.

Ready to unify your operations?

See how Bulk can transform your manufacturing floor with a personalized demo.