Equipment Maintenance Log

Track preventive maintenance, repairs, and equipment history to maximize reliability and uptime.

About This Template

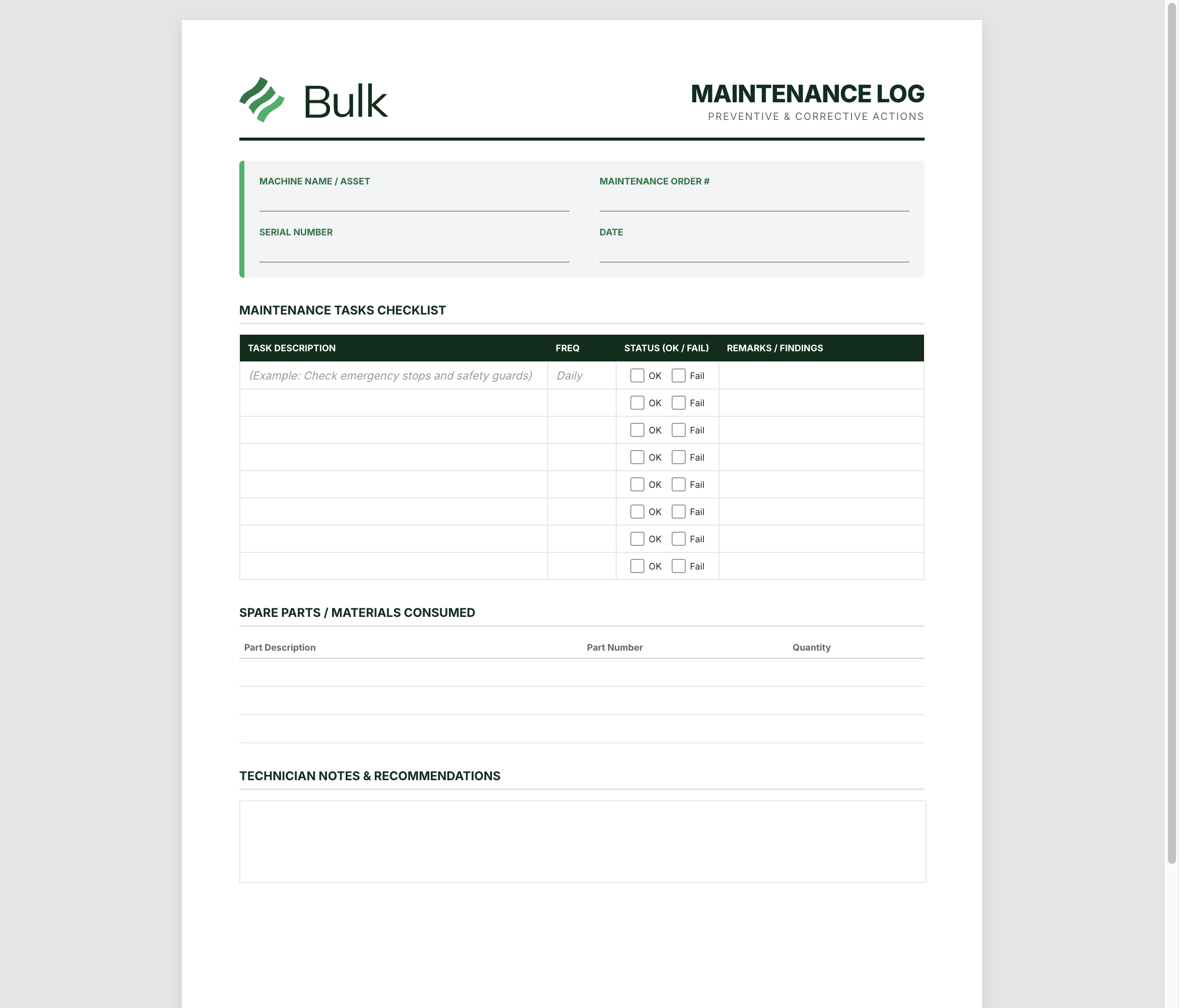

The Equipment Maintenance Log is essential for tracking all maintenance activities on critical production equipment. This template documents preventive maintenance tasks, repairs, parts replacements, and equipment performance over time, creating a comprehensive maintenance history. Regular logging enables predictive maintenance by identifying failure patterns, helps optimize PM schedules, and provides data for equipment reliability improvement. The log format captures work performed, parts used, downtime duration, and costs, supporting both regulatory compliance and continuous improvement of maintenance effectiveness.

Key Features

How to Use This Template

- Create dedicated log for each critical piece of equipment

- Record all PM tasks immediately upon completion

- Document any repairs, adjustments, or part replacements

- Track downtime duration and production impact

- Note any abnormalities or developing problems

- Review logs periodically to identify equipment reliability trends

Ideal For

Common Use Cases

Use this template in a live digital workflow

Start with this downloadable form, then transition to real-time production execution, quality tracking, and automated reporting with Bulk.

Ready to unify your operations?

See how Bulk can transform your manufacturing floor with a personalized demo.